Bottom suction submersible pump is used mainly in mine. We designed it on the basis of submersible well water pump. According to current customers’ needs, APK, one of the best submersible pump manufacturers, combined foreign advanced technology with our own unique skills, finally produced such kind of mine dewatering pump. Because of its submersible motor, our bottom suction submersible pump is able to work under water for long time. Usually, we suggest customer to use it along with protection tube.

Working Parameter:

Flow Capacity: 10-2500m³/h;

Head Range: 15-600m;

Well Diameter: φ175-800mm;

Temperature: -15-40℃;

Application

Bottom suction submersible pump can be used as main drainage water pump as well as emergency and rescue pump. Because of its light weight and small diameter, it is capable of explosive resistance when using in high gas level mine. Apart from this, we also apply bottom suction submersible pump for river, pond, lake and other smooth mouth water source area.

Features

1. Pump body and motor can be immersed totally into water. Water cooler submersible motor and oil filled submersible motor are chosen to be installed. Our pump are capable of working under water for long time without making any damage to motor.

2. We install diversion sleeve inside the bottom suction submersible pump, besides, we will also install bottom valve if customers need. Because the inlet of pump is at the bottom, so water on the working ground is able to be totally pumped. Meantime, the cooling effect of motor can also be guaranteed.

3. As we install pump and motor as one, there is no need to build a pump house any longer. Therefore, it is able to save more space and more cost. The whole structure is simple, making it easy to be disassembled in repairing and maintenance.

Working Principles:

- Before working, water must be filled through water injection tunnel into pump. Then when bottom suction submersible pump is operating, impeller rotates together with axial. High rotating impeller brings vacuum atmosphere around inlet, then water is primed under pressure.

- Water moves with rotated impeller, and then flows away from it under the force of centrifugal. Dynamic power is greatly strengthened in this process.

- After water flows outside impeller part, it comes into spiral diffusion chamber. Most of dynamic power is transferred into pressure power, then water flows out through drainage tube under great pressure.

- All the water flows out of pump and vacuum atmosphere is formed again at impeller part. Thus new round starts.

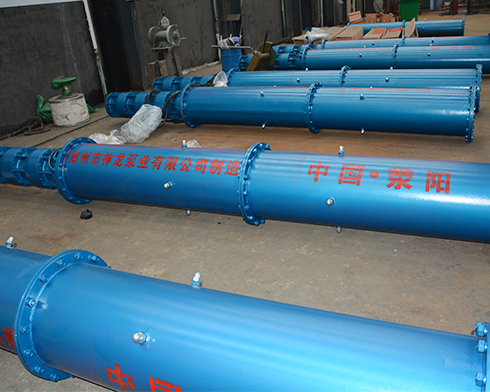

Bottom Suction Submersible Pump For Sale

APK, a professional submersible pump manufacturer, devoted to only producing best pump for you. Instead of using sampling check, we choose to test each of our pumps under different conditions. before selling, we will send back defective pump for reproducing. Each of our products is of high quality and high efficient. We promise to bring you the most suitable purchase experience.

Until now, bottom suction submersible pump for sale in APK has won great praise among customers. The head of each single stage is higher than normal, and we designed whole height of pump as low type, so that security and smooth level are able to be improved.

Larger diameter guarantees security. The diameter of our pump is larger even than national standard. This helps pump to be worked in relatively stable condition. Furthermore, we use HT200 as main casting material. Ductile iron helps improve load level of our pump. Unique designed check valve can greatly avoid our pump being broken by water hammer.

Structure of Bottom Suction Submersible Pump

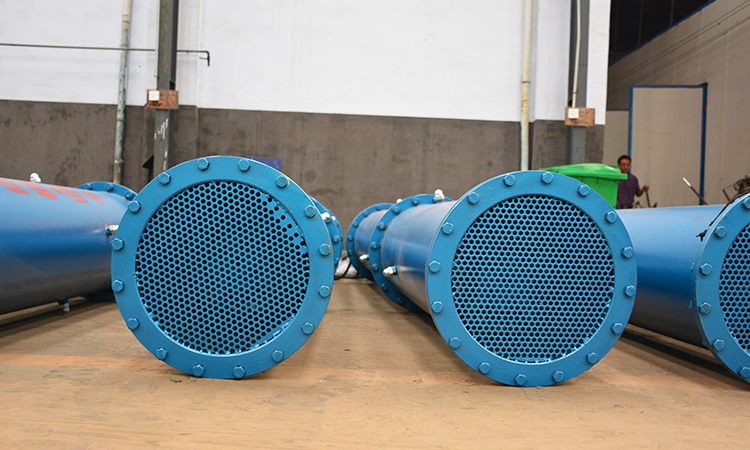

Bottom suction submersible pump is consists of three main parts, inlet and outlet, submersible motor and impeller. We installed several impellers on pump axial, then they rotate with movable axial when working. Filter is installed outside the inlet,so it can only pump clean water in. Smooth and wide pump body guarantees large capacity of our pump. We use high quality flange to connect two parts of pump together, so that it leaks out no water. Suction tube is linked with inlet, while drainage tube linked with outlet.

Want to know more details?

We suggest protection tube should be used along with mine dewatering pump. It can well protect well head, in case that other impurities fall into well. In addition, mining well may easily get collapsed for some reasons. When using protection tube, it can easily control water level pressure. And then sediment is not easy to flow back into pump.

Bottom Suction Submersible Pump Selection:

When choosing submersible pump, we must take some factors into consideration. Here APK will give you some suggestions on how to select.

First, The product you choose should be excellent in saving energy, thus your usage cost can be greatly saved. APK continuously updates our technology, keeps pace with social development, and pays attention on customers’ changeable needs. We carries on social responsibility, sticks to produce high efficient and energy saving pumps. Our pumps break restriction of traditional type, becoming newly high tech products.

Second, as for mine dewatering pumps, the selection of bearing is important. Bearing is used to support the whole axial. Essentially, it is used to bear the radial load, so that axial could rotate as it is required. Rolling bearings and plain bearings are to be chosen according to load. They have similar structures. But when loading heavy thing, we will choose rolling bearings for you.

All kinds of material and accessories we use are of high quality and low price. Therefore, our pumps are especially famous for high cost-effective. If you have any intention on our products or our company, please leave your message below and we will contact you as soon as possible.