Submersible centrifugal pump is widely used in cooling system, liquid transferring, industry cleaning system, electricity, metallurgy and coal etc. Centrifugal pump types are varies, they can be divided according to installation method and numbers of impellers. As a professional manufacturer, many kinds are listed on our centrifugal pump catalogue for chosen. We have affordable price and intimate after sale service, promising to give you the most comfortable purchasing experience.

APK, as one of professional and responsible submersible centrifugal pump manufacturers, exerts to improve the performance of our pumps all the time. We strictly monitors using experience of our pumps after buying in order to overcome shortcomings. Many of our pumps are used for municipal construction and has made great contribution to social development.

Working Parameter:

Flow Capacity: 10-2500m³/h;

Head Range: 15-600m;

Well Diameter: φ50-800mm;

Temperature: -15-40℃;

Application

- Fluid transferring

- Cooling system

- Industry cleaning system

- Aquaculture farms

- Fertilization system

- Metering system

- Industrial device

Advantages

- Impact and simple structure, easy to operate and maintain

- Wide range of flow and head, satisfy all sorts of needs

- Light corrosive fluid is able to be transferred

- Different methods on controlling

- Steady flow and work, no special vibration device need to be installed

- Low cost in installation and maintenance

- Space saving and cost saving

- Low noisy and environmental friendly

What is Submersible Centrifugal Pump

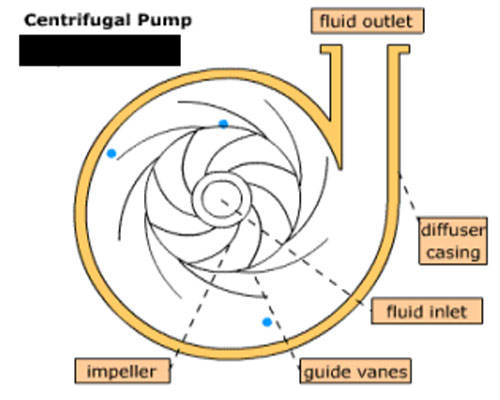

Centrifugal pump is named according to its impeller. When it is operating, this unique impeller gives water centrifugal force so that water can be drained out. It mainly consists of impeller, pump body, pump shaft, bearing, seal ring and stuffing box.

How Does a Submersible Centrifugal Pump Work

Have you ever consider how centrifugal pump works? Actually, special working principle relies on its impeller. When pump is operating, the impeller rotates rapidly. When water flows near impeller, rapidly rotated impeller gives water centrifugal force, making water flow away from the center. So that water could do little harm to impeller and the service life of water pump can be prolonged.

Submersible Centrifugal Pumps Price

In terms of submersible centrifugal pumps price, key factor we should bear in mind is produce costs. Unlike most pumps suppliers, APK owns the most strong strength factory. With automatic stator wielding line, automatic winding line and automatic assemble line, produce efficient is improved a lot and whole produce costs are reduced accordingly. Besides, if you want to save large money in buying centrifugal pumps, then acquiring a high quality water pump is extremely important. Imagine yourself buying a weak quality one, then after short time, you need to repair it or have trouble in its bad working condition, then you must spend more money in replacing with a brand new one. Therefore, our reasonable submersible centrifugal pumps price can also be a wise investment to you.

Submersible Centrifugal Pump Types

Submersible centrifugal pump can be divided into vertical type and horizontal type according to its installation method. Besides, there are single stage centrifugal pump and multistage type on the basis of numbers of impellers.

| Model | Flow rate | Head

(m) |

Power

(kw) |

Electricity

(A) |

Motor Head

(mm) |

Pump Head

(mm) |

Maximum Diameter

(MM) |

Weight

(kg) |

Motor Weight |

| 250QJ140-45/3 | 140 | 45 | 30 | 64.2 | 900 | 685 | 233 | 198 | |

| 250QJ140-60/4 | 60 | 37 | 77.8 | 933 | 1055 | 245 | |||

| 250QJ140-75/5 | 75 | 45 | 94.1 | 1288 | 1230 | 349 | |||

| 250QJ140-90/6 | 90 | 55 | 114.3 | 1388 | 1405 | 395 | |||

| 250QJ140-105/7 | 105 | 63 | 127.9 | 1448 | 1580 | 435 | |||

| 250QJ140-120/8 | 120 | 75 | 152.3 | 1528 | 1755 | 475 | |||

| 250QJ140-135/9 | 135 | 90 | 182.8 | 1648 | 1930 | 516 | |||

| 250QJ140-150/10 | 150 | 100 | 203.1 | 1718 | 2105 | 561 | |||

| 250QJ140-165/11 | 165 | 110 | 223.4 | 2280 | |||||

| 250QJ140-180/12 | 180 | 120 | 242 | 2455 |

Submersible Centrifugal Pumps For Sale

Because of their wide use range, submersible centrifugal water pumps are made into different types for different needs. As the leader of professional submersible pump manufacturer, we have all kinds of centrifugal water pumps for sale now.

Impellers we use are closed impellers, they are of high efficient and can be used for transferring clean water. We adopt advanced technology learned from abroad and successfully reduce the cost of producing centrifugal impellers. Therefore, the whole centrifugal pump price can be greatly reduced.

Centrifugal pump sales in APK now are still hot. We use modern technology and high-tech skills, together with high quality products and affordable price, won great praise among customers. Centrifugal water pump price list is given if required.

Stainless Steel Submersible Centrifugal Pumps

When used for transferring sea water or salt water, we suggest our stainless steel centrifugal pumps for you. With stainless steel castings outside, our pumps are able to transfer light corrosive liquid. And drinking water can also be transferred without being polluted. Because of large demand of ss pump, we specially perfect our stainless steel foundry. Now, our factory can provide customized large power centrifugal pumps for you. If you have special requirements on ss pumps on their head or flow rate, please let us know and our design project will give perfect pumps plan for you.

Want to know more details?

Vertical Submersible Centrifugal Pumps

As being submerged under water in working process, most submersible centrifugal pumps in our company are designed into vertical type. Pump body and units are linked as one and share the same shaft together. Hydraulic system is tested for hundreds of time for smooth working condition. Because of vertical design of it, our centrifugal pump is more space saving and cost saving than horizontal one, and is also easy to be installed or replaced. All you need to do in installation is to put it upright under water and then fix them tightly. If having trouble, just contact us for help any time.

Three ways can be used to control the flow of centrifugal pump, so that all kinds of needs can be satisfied.

1.Valve Adjustment

Valve of pump can be adjusted to change the flow of pump. This kind of method is easy to control and is convenience, so it is widely used among suppliers.

2.Rotating Speed Adjustment

Flow will be reduced when rotating speed of motor is turned small. It can reduce 65% of energy cost.

When pumps are used to transfer liquid with particles such as sand, small tunnel pumps are easily get stuck. On considering this, we designed pump internal structure and make it non clog type. Impeller inside is centrifugal one, therefore, transferred liquid do less harm to impeller when working and enables it to get long life expectancy. High pressure and low pressure non clog submersible centrifugal pumps can be chosen for different using conditions. If you still do not know which pumps to choose, we have professional staff to give you a hand. Contact us any time you need.

Submersible centrifugal pump is consists of six parts, each of them has their special functions and structures.

1.Impeller

Impeller is a vital part of a pump, and blade is a main part of impeller. Highly rotated impeller gives water centrifugal force, making water flow out of pump. Before installation, we will make a static balance experiments to test its performance. Both sides of impeller need to be smooth enough to reduce friction loss of water flow.

2.Pump Casing

It is used to support whole pump and serves as main body. APK use lost foam casting technique, so that casting we made is of high quality and smoothness.

3.Pump Shaft

Pump shaft is used to connect motor with pump body. It is linked with coupling for horizontal type. And it serves as an important carrier for transferring mechanical energy.

Want to know more details?

4.Bearing

We choose to use water lubricated bearings, so that water can not be polluted. And rubber bearings inside is especially excellent in wear resistance and vibration absorb.

5.Stuffing Box

Filler is put inside to stop water leakage. The filler we chose has enough chemical stability so that medium can not be polluted. And its lubricated performance is good so that it is wear resistance.

6.Axial Force Balancing Device

When pump is operating, water is pumped in under low pressure and flowed out under high pressure. Therefore, this device is installed to keep balance of pump for safety.

Submersible Centrifugal Pump Manufacturers

Since foundation, APK always sticks to regard client’s need as the most important thing. Compared with other manufacturers, we not only have advanced technology and strong strength factory, but also have modern management system and intimate after sale service.

We continuously learn from others and renew our products. After the products of APK are sold, we have professional staff to monitor the using experience of customers. When pumps are in trouble, resolving solution will be given by our personnel right away. We have comparatively long after sale maintenance and repairing time.

Submersible centrifugal pump produced by our company is sure to be of highest quality level. We have personnel waiting online in 24 hours for resolving all your problems. Intimate service and high quality products will sure to bring you the most comfortable purchasing experience. So if you have any intention or questions about our products and our company, please leave your message below and we will contact you as soon as possible.