Submersible pumps are used to transfer water. According to quality of transferred liquid, they can be divided as submersible clean water pumps, submersible saltwater pump, hot water submersible pump and submersible sewage pumps. As name suggests, submersible saltwater pump is used to transfer saltwater, or liquid with light corrosive nature. It is widely used in fire control on offshore platform, equipment cooling, desalination, mariculture, farmland irrigation, mining, garden design, geothermal, deep well water lifting and industrial water supply etc.

Working Parameter:

Flow Capacity: 10-700m³/h;

Head Range: 15-405m;

Well Diameter: φ50-200mm;

Temperature: -15-40℃;

Features

- Using 304 or 316 stainless steel as casting material, high corrosive resistance and is able to protect environment and water source.

- High single stage head guarantees working safety of pumps, carefully designed diameter increased torsional performance of pump shaft.

- Pure natural rubber as main material for making hard pump bush, thus corrosive performance of whole pump is increased.

- Using high efficient hydraulic model to design impeller, working cost is largely reduced.

- Check valve is installed inside to prevent pump from breaking when it suddenly stops.

- Accessories inside sea water submersible pumps can be changed and regroup according to head and flow.

Using Condition

- All kinds of sea water, light corrosive or clean water without impurities can be transferred, cooling water, rain water, underground gushing water from coal, iron and metal mine can also be well transferred.

- Liquid temperature should be no more than 25℃+5

- Solid impurity content should be no more than 0.01%

- PH level should be among 7.9-8.6

- Whole pump must be worked under totally under water

Submersible Saltwater Pump Working

- When the pump is on, sea water is flowed inside through inlet, large particle solid is filtered out.

- Then impeller rotates with operated motor. Water near impeller is thrown away and vacuum space is formed near impeller.

- Large pressure differential is formed between ambient atmospheric pressure and vacuum space. Outside water is pumped in from inlet under great pressure and new round of working process begins.

Submersible Saltwater Pump Materials

Corrosion is the biggest problem in salt water transferring. Two kinds of materials can be used to solve this problem, one is to use 316ss materials, the other is high corrosive materials.

Compared with high corrosive materials, 316ss is more cost-effective and can greatly reduce the cost of saltwater pumps. Therefore, APK chooses to use 316 stainless steel as casting materials. So that our pumps are of high corrosive resistance and is able to protect quality of water source from being polluted. Besides, service life of our pumps can be prolonged.

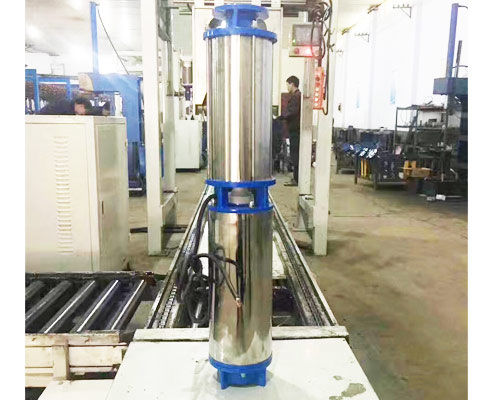

Submersible Saltwater Pump Structure

Sea water submersible pump is consists of submersible motor, water pump and water pipe. As pump needs to be immersed into water for long period of time, we choose to use water filled three phase asynchronous motor. Clean water needs to be filled inside to cool and lubricate pump shaft. PE insulated nylon sheath is installed as motor winding. Water resistant electromagnetic wire helps resist hot water to some degree. Upper part of motor adopts sanding ring and skeleton oil seal in case of leakage. Multistage centrifugal closed impeller improves head of pump.

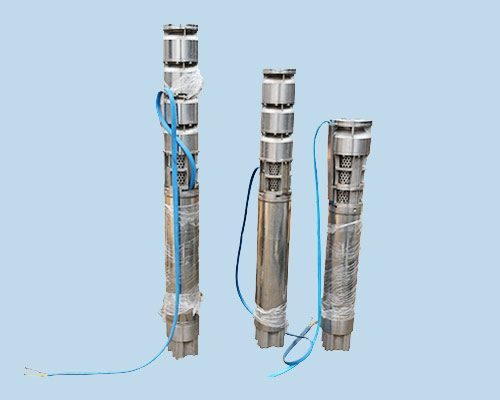

Submersible Seawater Pumps For Sale

Salt water submersible pump for sale now in APK mainly refers to our QJH series stainless steel submersible seawater pumps. When buying our pumps, long cable and lifting pipe would be given so as to be used in aquaculture.

Our salt water pumps are designed based on deep well submersible pumps. Many diameters and head or flow can be chosen to satisfy different needs. Accessories inside can be changed or combined with others according to customers’ requirement. Installation instruction would be patiently taught by our professional staff to make sure safety working.

Salt Water Submersible Pump Specifications

| Model | Flow rate | Head

(m) |

Power

(kw) |

Electricity

(A) |

Motor Head

(mm) |

Pump Head

(mm) |

Maximum Diameter

(MM) |

Weight

(kg) |

Motor Weight |

| 200QJ50-26/2 | 50 | 26 | 5.5 | 13.6 | 475 | 420 | 184 | 79 | |

| 200QJ50-39/3 | 39 | 10 | 24.7 | 673 | 560 | 99 | |||

| 200QJ50-52/4 | 52 | 13 | 29.7 | 703 | 895 | 124 | |||

| 200QJ50-65/5 | 65 | 15 | 33.9 | 876 | 1040 | 154 | |||

| 200QJ50-78/6 | 78 | 18.5 | 41.6 | 926 | 1085 | 174 | |||

| 200QJ50-91/7 | 91 | 22 | 48.2 | 1177 | 1330 | 233 | |||

| 200QJ50-104/8 | 104 | 25 | 54.5 | 1237 | 1475 | 246 | |||

| 200QJ50-117/9 | 117 | 25 | 54.5 | 1237 | 1620 | 255 | |||

| 200QJ50-130/10 | 130 | 30 | 65.4 | 1317 | 1765 | 280 | |||

| 200QJ50-143/11 | 143 | 37 | 79.7 | 1452 | 1910 | 310 | |||

| 200QJ50-156/12 | 156 | 37 | 79.7 | 1452 | 2055 | 320 | |||

| 200QJ50-169/13 | 169 | 37 | 79.7 | 1452 | 2220 | 330 | |||

| 200QJ50-182/14 | 182 | 45 | 96.9 | 1573 | 2365 | 356 |

Advantages of Salt Water Submersible Pump in APK

- Upscale design and producing skill ensures high quality of our pump

- High corrosive resistance performance

- Gap between impeller is designed large enough for small solid particles

- Stable output flow, seldom pulsating phenomenon happens

- No need to add plus water inside manually

- Large flow and small vertical shape

- High reliable for high-grade ball bearings and high speed permanent magnet motor

- Low noisy and environmental friendly

- Space saved and cost saved

- Competitive price and intimate after-sale service

As a professional submersible pump manufacturer, APK is still stepping upgrade technology and service modes in order to offer you the most comfortable purchasing experience. We are also brave enough to carry on social responsibilities and try our best to protect environment and water source. So if you have any intention on our products or our company, please leave your message below and we will contact you as soon as possible.