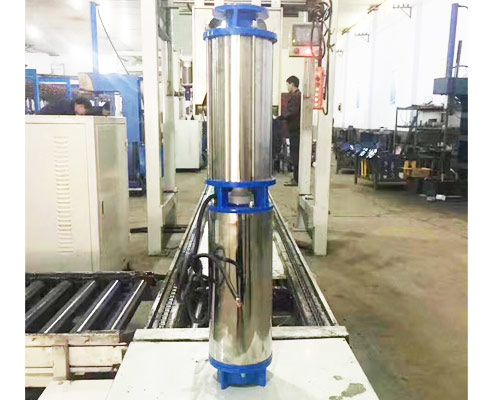

Two types of installation are often adopted by manufacturers, one is vertical submersible pumps, while the other, horizontal submersible pumps. Vertical submersible pumps, because of their space-saving shape and simple structure, are widely used under water. The main function of vertical submersible pumps in APK is to lift water from relatively low places, such as river, pond and well. Other situations like cultivation and septic tank are also in great need of submersible vertical pump.

Working Parameter:

Flow Capacity: 10-700m³/h;

Head Range: 15-405m;

Well Diameter: φ50-200mm;

Temperature: -15-40℃;

Application

- Vertical submersible pumps can be used for draining extra water or sewage in construction site, municipal flood control, as well as pumping clean water or well water;

- Vertical submersible pumps are also designed as submersible sewage pump. Therefore, they can be used as sewage drainage devices in some factories and companies.

- Stainless steel vertical submersible pumps are used to transfer corrosive water as well as fluid with food grade level.

- They can also be used to drainage sewage water in basement and tunnels around stations and skyscrapers.

Precautions of Usage

Some notes have to be reminded in using vertical pumps. First, when pump is working without water, working time must be strictly controlled within rated time. Or submersible motor may be burnt. We suggest water should be filled before using in case that such situation happens. But pumps from APK has current protection, overheating protection and short circuit protection devices inside motor control device to well protect our pumps.

Secondly, the volume of priming reservoir should be large enough, and make sure water level keeps high when pump is working. So that pump would not stop and restart frequently and cooling effect of our pump can be guaranteed.

Besides, humidity sensor and temperature sensor are installed inside. When they sound the alarm, pump should be stopped immediately. And we will teach you how to check and repair your pumps under such occasion.

Vertical vs. Horizontal Submersible Pumps

Apart from shape, there are still many differences between vertical and horizontal submersible pumps.

-

Connection

Pump and motor are connected superimposed from bottom to top vertically. While horizontal one uses coupling to connect motor with pump body, and both of motor and pump are installed on the set.

-

Occupation

As vertical submersible pump is used vertically, more space is saved when using. And there is no need to lay a foundation before installing. On the contrary, horizontal type needs more space for its set. Normally, horizontal pump is used on the ground, thus more space would be occupied compared with vertical type.

-

Repairing

When a horizontal pump needs to be repaired or maintained, we need only to open pump casting because motor part and pump part are separated. The repairing of submersible vertical pump is a bit more complex than horizontal one. But there is no need to worry about that, APK makes vertical pump simple structure, all accessories are easy to be repaired from our company.

-

Installation

Submersible vertical pumps are installed as one, so the whole installation is easy and fast. While horizontal one needs to be precisely adjusted after installation.

Both of the two kinds of pumps have their irreplaceable advantages, customers could choose one of them according to using condition.

Features of Vertical Submersible Pumps

1.Cost-Saving

When pumps are used for changeable water level place, they must be installed on low water level. Vertical submersible water pumps installed under such occasion can greatly save the space of pump station area and reduce earthwork. This helps reduce infrastructure investment. Therefore, many centrifugal water pump and mixed flow submersible pumps all use vertical type.

2.Long Service Life

Water lubricated bearings can be used for vertical type only, that’s another reason for large capacity pump using vertical style. The whole structure of water lubricated bearings are simple. So they carry less load and less wearing when working. This helps prolong the service of vertical pump.

3.Smoothly Running

Because of multistage and long pump shaft, some high pressure pumps with small capacity are unable to run smoothly when working. On considering this problem, APK makes pump shaft of our submersible vertical pumps subjected to certain pulling force. So that submersible pump from APK are promised to run smoothly when it is working.

4.Cavitation Resistance

In order to prevent our pump away from cavitation, we low down the position of first stage impeller’s inlet. Then cavitation allowance is able to be reduced and pump’s working security is guaranteed.

5.Space Saving

Sometimes the occupation area of pumps may be restricted, then vertical submersible pumps are chosen to solve the problem. They can save the working space to a large extent.

Vertical Submersible Pumps Specifications

| Model | Flow rate | Head

(m) |

Power

(kw) |

Electricity

(A) |

Motor Head

(mm) |

Pump Head

(mm) |

Maximum Diameter

(MM) |

Weight

(kg) |

Motor Weight |

| 300QJ200-20/1 | 200 | 20 | 18.5 | 41.7 | 815 | 360 | 281 | 145 | |

| 300QJ200-40/2 | 40 | 37 | 77.8 | 933 | 560 | 202 | |||

| 300QJ200-60/3 | 60 | 55 | 115 | 1388 | 1005 | 350 | |||

| 300QJ200-80/4 | 80 | 75 | 154.1 | 1528 | 1205 | 428 | |||

| 300QJ200-100/5 | 100 | 90 | 183.8 | 1648 | 1405 | 470 | |||

| 300QJ200-120/6 | 120 | 110 | 222.1 | 1751 | 1605 | ||||

| 300QJ200-140/7 | 140 | 125 | 249.5 | 2336 | 1805 | ||||

| 300QJ200-160/8 | 160 | 160 | 317.5 | 2476 | 2005 | ||||

| 300QJ200-180/9 | 180 | 160 | 317.5 | 2476 | 2205 | ||||

| 300QJ200-200/10 | 200 | 185 | 367.14 | 2566 | 2405 | ||||

| 300QJ200-240/12 | 240 | 220 | 436.5 | 2671 | 2605 |

Vertical Submersible Pumps Manufacturers

In order to produce high quality submersible pumps, the producing skills of manufacturers are extremely important. APK devoted to strictly controlling the quality of each pumps. In short period of time, APK has become one of the leaders of submersible pump suppliers. Our products are sold overseas and win great praise among customers.

Submersible pump winding has to be installed and checked carefully, or vertical pump may be burnt. APK combines manual and machine together, greatly improve the efficiency and accuracy of winding.

The strength of our factory ranks the first among any other in China. The quality of each material we use is higher than national standard. Our copper wire owns the highest purity. We changed manual work into machine assembly work, thus the whole working efficiency is improved.

Each of our pump is tested in our test center, this test center is in line with National Standard B. Instead of choosing sampling test as most factory normally does, APK requires every single pump must be tested through computerized test system. Head, capacity, electric and power of pumps are all under carefully monitored.

For cast iron vertical submersible pumps, they need to be painted after testing. We use machine to do the job so that many pumps can be painted simultaneously.

Many kinds of vertical submersible pumps are for sale now in APK. We will offer you the most comfortable purchasing experience. We not only have best quality products and intimate after-sale service, but also do we offer tight packing and transportation. If you have any intention or problems about our products and APK, please leave your message below and we will contact you as soon as possible.