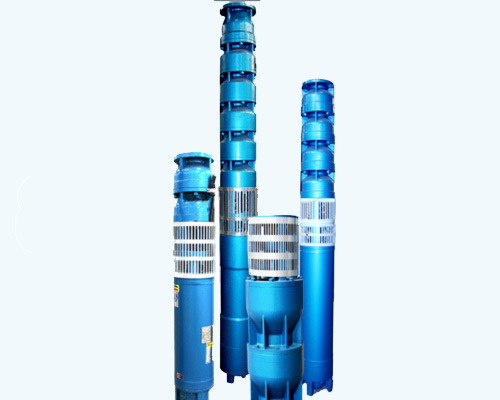

As an important accessory, motor is installed with pump body as one. Submersible motor pump is used to be immersed into water for irrigation and residential or industrial water supply. With low noisy, easy installation and reliable performance, submersible motor pump becomes increasingly popular. With motor installed inside, there is no need to build a house, thus more space and cost is saved.

Working Parameter:

Flow Capacity: 10-700m³/h;

Head Range: 15-405m;

Well Diameter: φ50-200mm;

Temperature: -15-40℃;

Features

- Rusty resistance.

- Unique thrust bearing makes sure to bear high pressure of axial thrust.

- High efficiently energy saving

- Copper rotor and low energy saving silicon steel laminated ensures high starting torque.

- Larger shaft leads to better dynamic transfer.

- Excellent cooling performance

Application

Submersible motor pump is widely used in underwater drainage, agricultural irrigation, pressurized device, residential and industrial water supply as well as mining.

Working Parameter:

Flow Capacity: 10-700m³/h;

Head Range: 15-405m;

Well Diameter: φ50-200mm;

Temperature: -15-40℃;

Working Parameter:

Flow Capacity: 10-700m³/h;

Head Range: 15-405m;

Well Diameter: φ50-200mm;

Temperature: -15-40℃;

Working Parameter:

Flow Capacity: 10-700m³/h;

Head Range: 15-405m;

Well Diameter: φ50-200mm;

Temperature: -15-40℃;

Working Parameter:

Flow Capacity: 10-700m³/h;

Head Range: 15-405m;

Well Diameter: φ50-200mm;

Temperature: -15-40℃;

Working Parameter:

Flow Capacity: 10-700m³/h;

Head Range: 15-405m;

Well Diameter: φ50-200mm;

Temperature: -15-40℃;

-

Power Supply Voltage

According to power supply voltage, submersible motor pump can be divided into single phase and three phase submersible water pumps. If letter“D” is added after a product model, it refers to single phase. Or it is three phase water pump. 3 phase pump is 380v, residential single phase pump is usually 220v. Compared with single phase, 3 phase is more energy saving and has better performance, thus is more widely used by pump manufacturers.

-

Internal Structure

Submersible motor pump can also be divided by internal structure. There are all together four types of motors. The first is water cooler submersible motor. This kind of motor is filled with clean water or rusty resistance lubricating oil, then it is able to be used for a long time without being burnt. Submersible pumps with submersible water filled motor has to be used under three phase of 50HZ and 380 volt.

The next type is oil filled submersible motor. It is sealed structure filled with insulating oil, which means oil will be filled when motor becomes hot for working a long time. Water filled motor and oil filled motor are usually used under water.

Air cooler motor is also called dry motor. It is filled with air inside, and has simple structure that quite the same as ground motor. When dry motor is installed together with pump body, it is called dry motor submersible pump. This kind of pump uses water flow outside pump case to cool down without touching stator and rotor. The price of air cooler submersible pump is lower than oil cooler one, but it can only be used when low head and low load is required.

The last one, shielded motor. This kind of motor is used to transfer toxicity, rusty, radioactivity, flammable and explosive liquid. So stator and rotor has to be shielded in case of being rotted. The stator of the motor is closely sealed by a seal room, the seal room is formed by end ring, chassis and thin wall shield which are made by non-magnetic stainless steel. Inside the motor is fulfilled with solid material. When it is installed with submersible pumps, it can be used to transfer liquid without solid. Shielded motor can be divided into horizontal and vertical type.

-

Configuration Method

Depend on position of motor installation, it can be divided into up and down pump type;

It can also be classified into exterior type, interior type, half interior type and tubular type. When fluid straightly flow out pump without going through motor, it is called exterior type. Interior type is used when water flows through the surface of electric motor. It requires motor to be of high cooling performance, it is suitable to be used in large area drainage situation and is famous for its reliable. The cooling capacity of half interior type is better than exterior type.

-

Usage

According to the usage of pump, submersible electric motor can be divided into seven types. They are submersible well water pumps, clean water submersible pumps, sewage or waster water submersible pumps, mine dewatering pumps, axial flow submersible pumps, well water high pressure submersible pumps and giant submersible pumps.

The main submersible motor pumps for sale in APK are water cooler pump submersible(short as QS submersible pumps) and oil filled submersible pumps(short as QY submersible pumps).

Want to know more details?

Submersible Motor Pump Price

Do you have puzzle in finding the reasonable submersible motor pump price list? It is a common phenomenon that customers would like to find cheap price products at first time, but in long term sight, buying a cheap pump is actually spending more money than buying a costly quality pumps. Though cheap for purchase price, they need to pay much in repairing and maintaining, which can be rather costly one can imagine. For APK pumps, our motor pumps are able to use for more than eight years when transferring clean water, which is far longer than normal types. Therefore, buying quality submersible motor pump is saving money for you. Detailed submersible motor pump price list will be given if you need.

Submersible Motor Pump Working

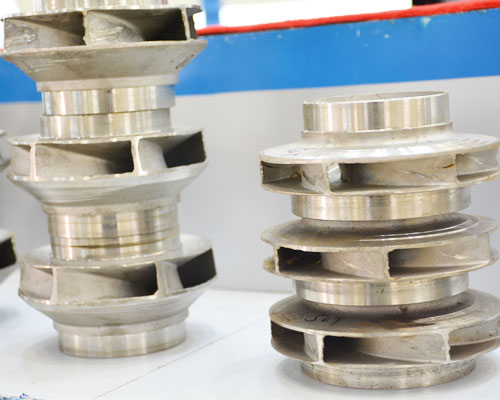

Like most submerged pumps, submersible motor pump must be immersed into water for its whole working period. Motor as the key factor, playing important role in driving other parts working. Water is sucked in under great pressure, after flowing near impeller, fast speed rotate impeller brings transferred liquid moves together and throw it away with large force. After water is thrown out of pump body, new round of transfer starts again. Hundreds of hydraulic experiments are made to make sure that whole working process is smooth and stable.

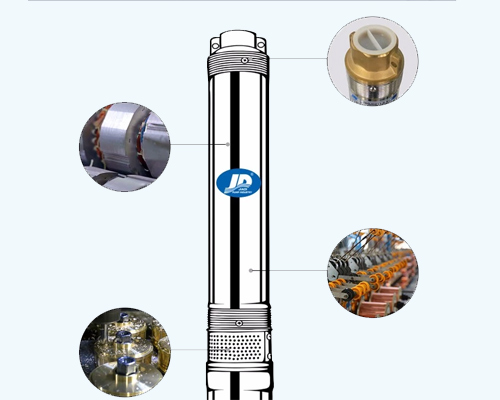

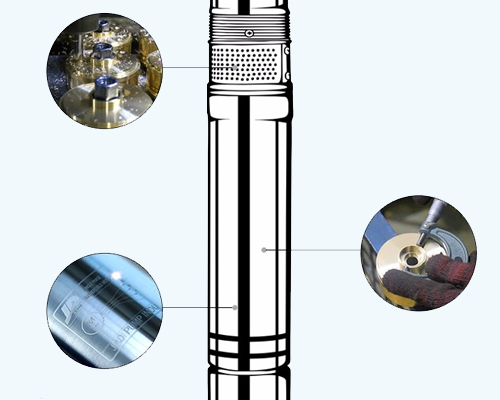

Internal Parts Design

Submersible motor pump parts are mainly include pumps body, motor, impeller, stator, shaft and copper wire etc. As it is designed as vertical types, pumps body and motor are linked together to share the same shaft. Raw materials are selected to use only, which includes 304 stainless steel motor rotor head, 100% virgin high strength PPO plastic impeller, NO. 800 silicone steel sheet as well as 100% copper wire and winding. High precision and efficient processing machining to enable good performance of each parts.

How To Get Pump Repaired

Submersible pump can be broken for several reasons, for some common fault, customers can find the reason and solution in common fault of pumps and repair by oneself. If impossible to repair by your own, or unable to find fault, you may contact a professional pumps manufacturer like us to help solve problems. Of course submersible motor pump repair price can be much higher especially when it gets broken frequently, so we strongly suggest you to buy a high quality pump at the beginning. Contact us any time for brilliant water pumps and for best submersible motor pump repair.

Submersible Motor Pump For Borewell

As name suggests, submersible motor pump for borewell is mainly used under well. In installation process, we would cover rubber tube outside pump body, protecting both pump body and well wall from being collapsed. For special pump requirement, we spend large money and manpower in improving stainless steel foundry. With excellent ss produce technology, we are able to produce all sorts of customized pumps for you. If you have need, just call us immediately and tell us all your requirements, design project will design pumps specially for you.

High Quality Submersible Motor Pump Set

Design: Every part is delicately designed and proved to get best performance

Material: Stainless steel 304 motor rotor head, PPO plastic impeller, raw materials are chosen only

Control: 95% spare parts are self made to control quality and costs.

Machining: High precision and efficient processing machining

Check: Spare parts, motors, finished pumps are 100% checked and tested strictly

Assembling: Standard and experienced assembling, put on the JIADI brand, all pumps are well packed after careful testing.

Maintenance of Submersible Motor Pump

In order to prolong the service life of submersible pump, some maintenance method needs to be done. APK based on the belief of “All for Customers”, regularly help customers maintain pump.

- We will check insulation resistance when pump stops running for a while.

- Monitor its working condition to make sure there is not any irregular noisy or shake. If any, we will repair it right away.

- Regularly check, repair or change mechanical sealing.

- Clean up rusty droppings and dirty spots, make sure each accessory is tied tightly.

APK offers the most comprehensive submersible motor pump, there is always one that suits you the most in our company. Affordable price and high quality is and will always be our strength. If you have any intention or any questions about our products, please leave your message below, and we will contact you as soon as possible.